During the operation of rice drying kilns, the process of transporting rice from the dryer to jumbo bags or storage warehouses usually requires a large amount of labor, is time-consuming, and is prone to spillage. Especially during peak seasons, slow rice discharge can directly affect the production schedule.

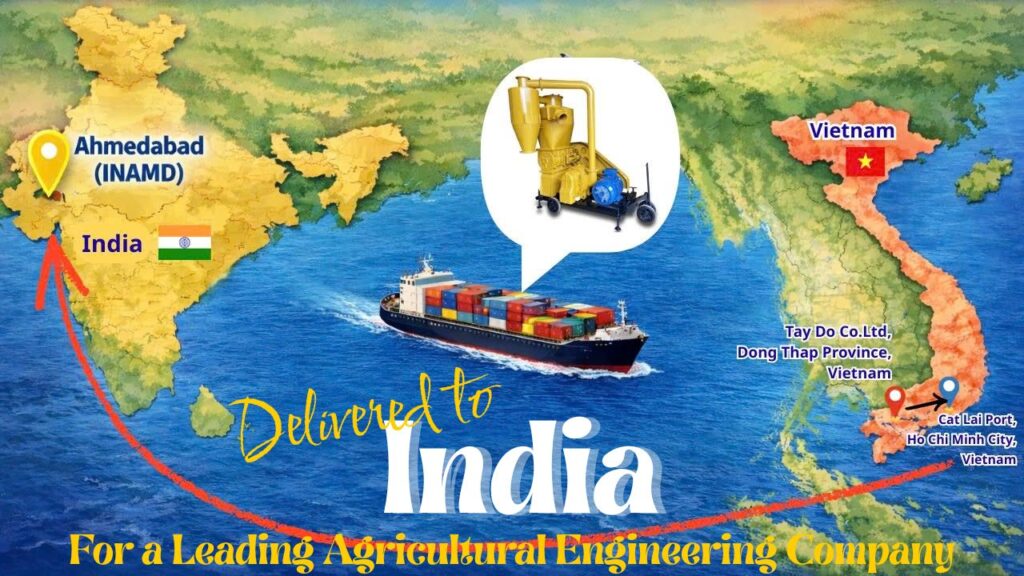

Recently, a customer in An Giang operating a large-scale drying kiln chose the 9–10 tons/hour rice suction and discharge machine from Tay Do Mechanical to address this issue. The machine is designed to directly suction rice from inside the drying kiln and continuously discharge it into jumbo bags, helping the rice handling process become faster, more efficient, and more stable.

After being put into operation, the system has delivered several clear benefits:

-

Significantly reduces manual handling labor

-

Fast rice discharge with stable and consistent flow

-

Minimizes spillage and material loss

-

Keeps the drying kiln area neat and easier to organize for production

So, what capacity of rice suction and discharge machine should be chosen?

This is a question that many drying kiln owners are concerned about when investing in equipment.

In practice, the required machine capacity needs to match the scale of the drying kiln, the rice throughput, and the discharge method.

For drying kilns that require continuous rice handling and discharge into jumbo bags or storage warehouses at moderate distances and heights, a 9–10 tons/hour rice suction and discharge machine is a reasonable choice because:

-

It effectively meets rice throughput requirements during a working shift

-

The machine operates stably without overloading

-

It saves investment costs compared to higher-capacity machines

-

It is easy to move and flexible to install in different production areas

Depending on the conveying distance, discharge height, and material characteristics, the appropriate machine capacity should be selected to ensure long-term efficiency.

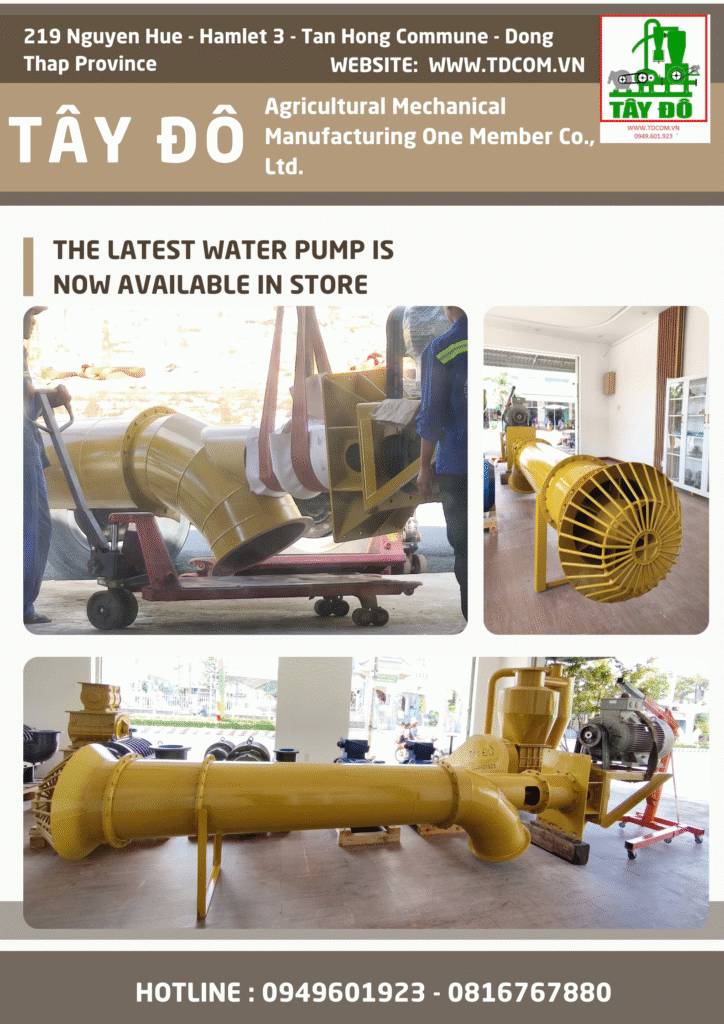

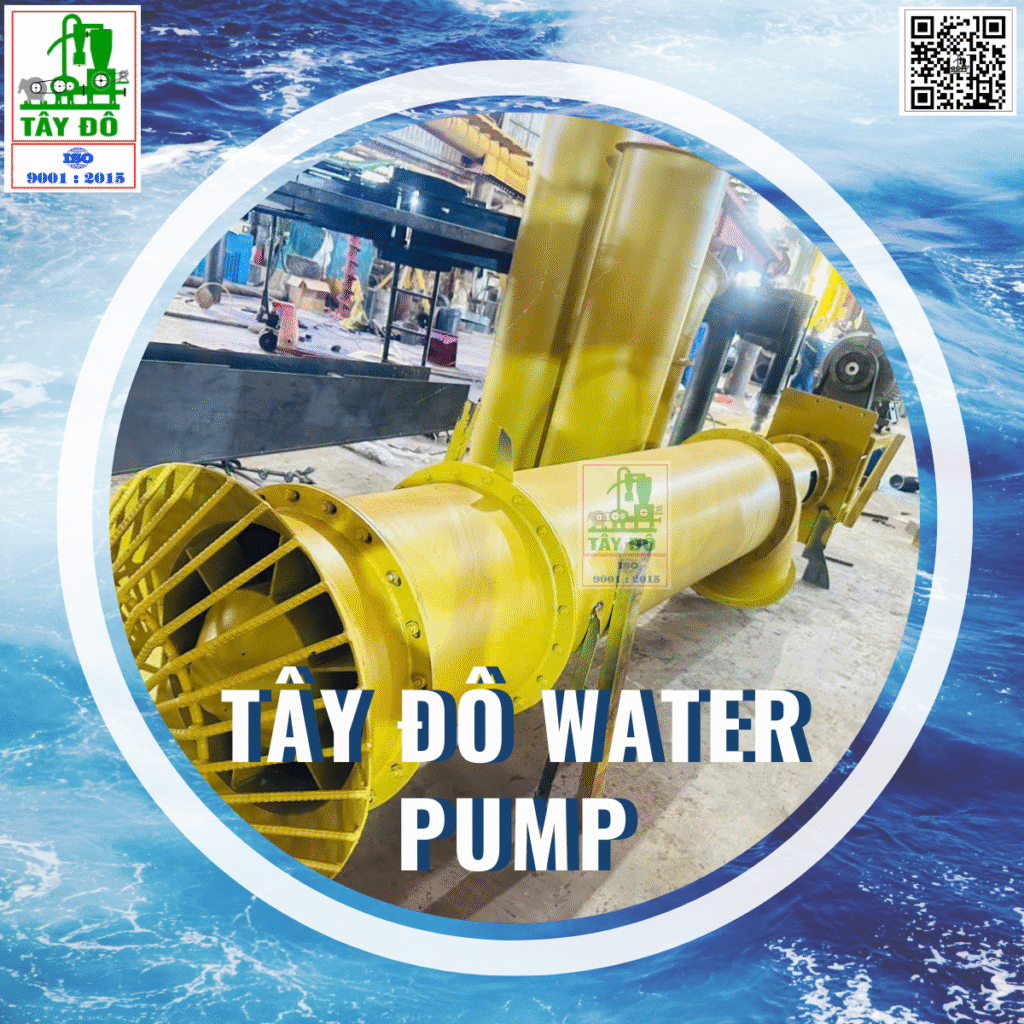

Tay Do Mechanical specializes in designing and manufacturing material suction and conveying machines tailored to the actual needs of each customer, suitable for drying kilns, rice warehouses, and agricultural product purchasing facilities.

If you are looking for suction–blowing machines or systems for conveying bulk materials such as rice husk, corn, rice, fertilizers, ash, stone powder, or pellet feed,

please contact Tay Do Agricultural Mechanical Engineering for consultation on the most suitable solution.

TAY DO’S COMMITMENT

TAY DO’S COMMITMENT

TAY DO AGRICULTURAL MECHANICAL MANUFACTURING CO., LTD

Tiếng Việt

Tiếng Việt